Have questions or need assistance? Our team is here to help you. Reach out to us for any inquiries, and we’ll get back to you as soon as possible with expert guidance and support.

A core division of Taco Metals Asia, Sabina Pak Limited is a specialized trading and distribution company operating across Pakistan’s structural steel industry. With deep-rooted expertise in the import, stocking, and supply of structural steel, Sabina Pak plays a critical role in supporting infrastructure, construction, and industrial projects throughout the country.

With its headquarters in Lahore, the company maintains strong ties with major global steel manufacturers and ensures a consistent supply of high-quality materials to its clients. Sabina Pak Limited is committed to providing customized steel solutions backed by timely delivery, technical expertise, and exceptional service.

As part of the Taco Metals Asia Group, Sabina Pak continues to strengthen Pakistan’s supply chain with international-grade structural materials—supporting both public and private sector growth initiatives.

| GRADE L1 | GRADE L2 | GRADE L3 | GRADE L4 | |

|---|---|---|---|---|

| Si | 3.2-3.6 | 2.8-3.2 | 2.4 – 2.8 | 2.0 – 2.4 |

| Mn | 0.5 – 1.0 | 0.5 – 1.0 | 0.5 – 1.0 | 0.5 – 1.0 |

| S | 0.03 MAX | 0.03 MAX | 0.03 MAX | 0.03 MAX |

| P | 0.10 MAX | 0.10 MAX | 0.10 MAX | 0.10 MAX |

| C | 3.5 – 4.5 | 3.5 – 4.5 | 3.5 – 4.5 | 3.5 – 4.5 |

| GRADE L1 | GRADE L2 | GRADE L3 | GRADE L4 | |

|---|---|---|---|---|

| Si | 3.2-3.6 | 2.8-3.2 | 2.4 – 2.8 | 2.0 – 2.4 |

| Mn | 0.5 – 1.0 | 0.5 – 1.0 | 0.5 – 1.0 | 0.5 – 1.0 |

| S | 0.03 MAX | 0.03 MAX | 0.03 MAX | 0.03 MAX |

| P | 0.10 MAX | 0.10 MAX | 0.10 MAX | 0.10 MAX |

| C | 3.5 – 4.5 | 3.5 – 4.5 | 3.5 – 4.5 | 3.5 – 4.5 |

| Description of products | Diameter (D), mm | Lenth (L),mm | Steel Grade |

|---|---|---|---|

| Round billets | 30 – 85 | 4000 – 12000 | St 3 sp/ps; St 5 sp/ps 380-941) 10, 20, 45 GOST 1050 -882) |

| 90 – 125 | 4000 – 8000 | ||

| 130 – 270 | 3500 – 6000 | ||

| Round Billets for Seamless pipe | 90 – 140 step 5 mm | 4000 – 120000 | |

| 50 – 270 step 10 mm | 3500 – 6000 |

| Type of slab | Thickness, H | Width, A | Length, L | Steel Grade |

|---|---|---|---|---|

| Concast | 235° | 1550 -1900 | 8200 | St 3 sp/ps; 08 YU; A36; A572 and other carbon, low and high alloyed steel grades in accordance with Russian, Ukrainian and intemation al Standards subject to agreement |

| 250 | ||||

| 280° | ||||

| 220 | 1550-1850 | 2000-12000 | ||

| 250 | ||||

| 300 | ||||

| Rolled | 130-320 | 1000-1550 | 3600 | |

| 120-320 | 700-1300 | 1250-6000 | ||

| 210-215 | 1250-1270 | 6000 |

| Standard | Steel grade | Dimensions. mm | ||

|---|---|---|---|---|

| Thickness | Width | Length {for sheets) | ||

| GOST 1577 GOST 1653 GOST 19903 | S11/20 kp”pWsp GOST 380-94″ OBkp, °Bps. 08. 10kp. lops, 10, 15kp. 15ps, 15. 20kp.20ps, 20. 30 GOST 1050-88′ DIN 17100′ 1)Tabe 1,2 Table 2,3) table 10 | 2.0- 2.7 | 1000 – 1250 x coll | 2000-4000 |

| 2.7 – 3.2 | 1000-1300 x cell | |||

| 3.2 – 3.5 | 1000-1320 x cell | |||

| 3.5.3.8 | 1000-1350 x cell | 2000-5000 | ||

| 3.8 • 4.0 | 1000-1350 x cell | 2000-6000 | ||

| 4.0 . 4.5 | 1000-1400 x cell | 4000-6000 Coil weigh – 7.0 to 8.5 mt Coil Diameter – Inner. 700. 710mm. outer: 1200-1300mm | ||

| 4.5 – 5.0 | 1000-1450 x cell | |||

| 5.0.8.0 | 1000-1500 x cell | |||

| DIN 17100 DIN 1614 JIS G3101 ASTM A36 ASTM A568/A568M ASTM A569/AS69 ASTM A570/A570M JIS 631 32 ENI 0025 | ST.372, RST.372 ST.442. ST.44.3 ST.50.2 ST.52.3 ST,22,RRST.23,ST,24 SS330. 88400 A36 SAE 1006.1025 A569 GR.30,33,36.40.45.60 SPHT I – SPHT2 S235JO,S235JR,S235JRG2 S275JR,S275JO, S275JRG3,S3355JR,S355JO S355J2G3 | 1,5 – 12,0 | 1000 – 1800 | 3500 – 6000 3500 – 6000 3500 – 6000 3500 – 6000 3500 – 6000 3500 – 6000 3500 – 6000 3500 – 6000 3500 – 6000 |

| 1,5 – 12,0 | 1000 – 1800 | |||

| 1,5 – 12,0 | 1000 – 1800 | |||

| 1,5 – 12,0 | 1000 – 1800 | |||

| 1,5 – 12,0 | 1000 – 1800 | |||

| 1,5 – 12,0 | 1000 – 1800 | |||

| 1,5 – 12,0 | 1000 – 1800 | |||

| 1,5 – 12,0 | 1000 – 1800 | |||

| 1,5 – 12,0 | 1000 – 1800 |

| Standar; | Steel grade | Dimensions mm | ||

|---|---|---|---|---|

| Thickness | Width | Length (For shEEts) | ||

| GHOST 8568 | St 1//3/4 KP/PS/SP

sT 5 sp/ps

GOST 380-94 |

3.5 – 8.0 | 1000 – 1300 Coil | 4000 – 6000 |

| CLASSIFICATION, STANDARD | STEEL GRADE | DIMENSIONS | MM | |

|---|---|---|---|---|

| THICKNESS H | WIDTH A | LENGTH L | ||

| American Bureau of Shipping | AB/A, AB/B | 8. 51 | 2000 -3200 | 6000 -12000 |

| AB/AN, AB/BN, AB/DN,AB/E, AB/AHN32, AB/DHN32, AB/EH32, AB/AHN36, AB/DHN36, AB/EN36 | 8 – 40 | 2000 -3200 | 6000 -12000 | |

| A, B, D , AH32, DH32, AH36, DH36 | 8 – 26 | 1500 -2700 | 6000 -11800 | |

| Det Norske Veritas | NVA, NVB, NVD, NVA32, NVD32, NVE32, NVA36, NVD36, NVE36 | 8 – 40 | 2000 -3200 | 6000 -12000 |

| NVA | 4 – 50 | 1400 – 2500 | 3000 – 12000 | |

| Germanischter Lloyd | GL-A, GL-B, GL-D, GL-E, GL-A32, GL-D32, GL-E32, GL-A36, GL-D36, GL-E36 | 8 – 50 | 2000 -3200 | 6000 -12000 |

| GL-A, GL-B, GL-D, GL-A32, GL-D32, GL-A36, GL-D36 | 8 – 26 | 1500 -2700 | 6000 -11800 | |

| Lloyds Register of Shipping | LRA, LRB, LRD, LRE, LRA32, LRD32, LRE32, LRA36, LRD36, LRE36, LRA40, LRD40, LRE40 ‘ | 8 – 50 8 – 25 14 – 45* 14 – 50* | 2000 -3200 1500 -2700 1200 -2500 1200 -2500 | 6000 -12000 6000 -11800 6000 – 9000 6000 -12000 |

| American Petroleum Institute, Specification 2H | API2H-42, API2H-50 | 8 – 100 | 2000 -3200 | 6000 -12000 |

| American Petroleum Institute, Specification 2Y | API2Y-42, API2Y-50, API2Y-50T, API2Y-60 | 8 – 100 | 2000 -3200 | 6000 -12000 |

| CLASSIFICATION, STANDARD | STEEL GRADE | THICKNESS MM (H) | WIDTH MM (A) | LENGTH MM (L) |

|---|---|---|---|---|

| Bureau Veritas | BVA, BVAH32, BVD32, BVEH32, BVAH36, BVDH36, BVEH36 | 8 – 50 | 2000 -3200 | 6000 -12000 |

| BVD, BVD, BVE | 8 – 90 | 2000 -3200 | 6000 -12000 | |

| Maritime Register of Shipping, Russia | A, B, D, A27, D27, E27, A32, D32, E32, A36, D36, E36 | 8 – 50 | 2000 -3200 | 6000 -12000 |

| A40, D40, E40 | 8 – 40 | 2000 -3200 | 6000 -12000 | |

| A, B, D, A32, D32, A36, D36, | 8 – 30 | 1500 -2700 | 6000 -11800 | |

| A, B, D, E, A32, D32, E32 | 5 – 50 | 1200 -2500 | 3000 -10000 | |

| DIN 10113 | P275/355/460 N/NH/NL1 S275/355/460 N/NH | 4 – 50 | 1200-2500 | 4000-12000 |

| DIN 17100 | Rst37-2, Rst37-3, St37-3, St44-2, St44 -3, 5t52-3 | 10 -100′ 8 – 30 | 2000.3200 1500-2700 | 6000-12000 6000-11800 |

| St 33, St 37-2, Ust37-2, Rst37-2, St37-3, St44-2, 5144-3, St52-3, St 50-2, St 60-2, St 70.2 | 8 – 30 | 1500-2700 | 6000-11800 | |

| DIN 17102 | St E 255, St E 285, St E 315, St E 365, Wst E 255, Wst E 285, Wst E 315, Wst E 355 | 8-30 | 1500 -2700 | 6000 -11800 |

| St E 255 – St E 500, Tst E 255 – Tst E 500 | 4.50 | 1200 -2500 | 4000 -12000 |

| CLASSIFICATION, STANDARD | STEEL GRADE | THICKNESS MM (H) | WIDTH MM (A) | LENGTH MM (L) |

|---|---|---|---|---|

| DIN 17155 | HI. HII | 10 – 80 | 200 0-3200 | 6000 12000 |

| HI, HII 17Mn4, 19Mn6 | 8 – 30 | 1500 -2700 | 6000 -11800 | |

| DIN 17172 | Steel grades to be agreed | 10 – 32 | 1860 – 3200 | 6000 -12000 |

| DIN EN 10025 | S235, S235JR, S235JRG2, 8235J0, S235J2G3, S235J2G4, S275, S275JR, S275J0, S275J2G3, S275J2G4 S355, S355JR, S355J0, S355J2G3, S355J2G4, S355K2G3, S355K2G4 | 8 • 160′ 8 – 30 | 2000 -3200 1500 -2700 | 6000 -12000 6000 -11800 |

| S185, E295, E355, E360 | 8 – 30 | 1500 – 2700 | 6000 – 11800 | |

| S235J0, S235JR, S235JRG1, S235JRG2, S235J2G3, S275JR, S275J0, S275J2G3, S275JRG3, S355JR, S355J0, S355J2G3, S355J2G4, S355K2G3, S355K2G4 | 4 – 50 | 1200 – 2500 | 4000 – 12000 | |

| DIN EN 10028 | P235GH, P265GH, | 2000-3200 | 6000 -12000 | |

| P235GH, P295GH, P355GH, P365GH, P275N, P365N, P275NH P355NH | 1500 – 2700 | 6000 – 11800 | ||

| DIN EN 10083 | 1C22-1050; 2022-2C50; 3C22.3C50 | 1200 – 2500 | 4000 – 12000 | |

| DIN EN 10207 | SPH235, SPH265, SPH275 | 8 – 30 4 – 50 | 1500 – 2700 1200 – 2500 | 6000 – 11800 4000 – 12000 |

| ASTM A36/A36M, | A36, SA36 | 8 – 160 | 2000 -3200 | 6000 -12000 |

| CLASSIFICATION, STANDARD | STEEL GRADE | THICKNESS MM (H) | WIDTH MM (A) | LENGTH MM (L) |

|---|---|---|---|---|

| ASME SA36/SA36M | A36 | 8 – 30 | 1500 -2700 | 6000 -11800 |

| 4 – 50 | 1200 -2500 | 4000 -12000 | ||

| ASTM A131/A131M | A, B, D, E, AH32, DH32, EH32, AH36, DH36, EH36 | 8 – 50 8 – 30 | 2000 -3200 1500 -2700 | 6000 -12000 6000 -11800 |

| ASTM A283/A283M | A283-C | 8. 160 4. 50 | 2000 -3200 1200 -2500 | 6000 -12000 4000 -12000 |

| A283-A, A283-B, A283-C, A283-D | 8 – 30 | 1500 -2700 | 6000 -11800 | |

| ASTM A285/A285M | A285-C | 4 – 50 | 1200 -2500 | 4000 -12000 |

| ASTM A299/A299M | A299 | 8 – 30 | 1500 -2700 | 6000 -11800 |

| ASTM A 455/A455M | A455 | 8 – 30 | 1500 -2700 | 6000 -11800 |

| ASTM A514/A514M | A514-B, A514-M, A514-F, A514-H, A514-J, A514-R | 8 – 65* | 2000 -3200 | 6000 -12000 |

| ASTM A515/A515M ASME SA515/SA515M | A515-60, SA515-60, A515-65, 5A515-65, A515-70, SA515-70 | 8 – 160 | 2000 -3200 | 6000 -12000 |

| ASTM A516/A516M ASME SA516/SA516M | A516-55, SA516-55, A516-60, SA516-60, A516-65, SA516-65, A516-70, SA516-70 | 8 – 160 8 – 30 | 2000 -3200 1500 -2700 | 6000 -12000 6000 -11800 |

| A516-60, A516-70, | 4 – 50 | 1200 -2500 | 4000 -11800 | |

| ASTM A529/A529M | A529-42, A529-50 | 8-30 | 1500 -2700 | 6000 -11800 |

| CLASSIFICATION, STANDARD | STEEL GRADE | THICKNESS MM (H) | WIDTH MM (A) | LENGTH MM (L) |

|---|---|---|---|---|

| ASTM A537/A537M | A537-1, A537-2 A5373 | 8 -150* | 2000 -3200 | 6000 -12000 |

| A537-1 | 8 – 30 | 1500 -2700 | 6000 -11800 | |

| ASTM A572/A572M ASME SA572/SA572M | A572-42, SA572-42, A572-50, SA572-50, A572-60, SA572-60, A572-65, SA572.65 | 8 – 160 | 2000 -3200 | 6000 -12000 |

| A572-42, A572-50, A572-60, A572-65 | 8 – 30 | 1500 -2700 | 6000 -11800 | |

| A572.42, A572-50, A572-65 | 4 – 50 | 1200 -2500 | 4000 -12000 | |

| ASTM A573/A573M | A573-58, A573-65, A573-70, A572-65 | 8 – 30 | 1500 -2700 | 6000 -11800 |

| ASTM A662/A662M | A, B, C | 8 – 30 | 1500 -2700 | 6000 -11800 |

| ASTM A588/A588M | A, B | 8 – 200 4 – 50 | 2000 -3200 1200 -2500 | 6000 -12000 4000 -12000 |

| A, B ,C, D, K | 8 – 30 | 1500 -2700 | 6000 -11800 | |

| ASTM A709/A709M | A709-36, A709-50, A709-50W | 8 – 100 8 – 30 | 2000 -3200 1500 -2700 | 6000 -12000 6000 -11800 |

| BS 1501 | 141360A, 151360A, 15136013, 154360A, 154360B, 161360A, 161360B, 161400A, 161400B, 161430A, 141430B, 164360A, 1643608, 164400A, 164400B, 223460A, 223460B, 223490A, 223490A, 223490B, 224400A, 2244006, 224430A, 224430B, 224460A, 224460B, 224490A, 224490B, 225460A, 225460B, 225490A, 225490B | 8 – 160 | 2000 -3200 | 6000 -12000 |

| CLASSIFICATION, STANDARD | STEEL GRADE | THICKNESS MM (H) | WIDTH MM (A) | LENGTH MM (L) |

|---|---|---|---|---|

| BS 4360 | 40k 40B, 40C, 40D, 43A, 43B, 43C, 43D, 50A, 50B, 50C, 50D | 8 – 160 | 2000 -3200 | 6000 -12000 |

| 40A, 50B, 43C, 50A | 4 – 50 | 1200 -2500 | 4000 -12000 | |

| CAN/CSA-G.40.21-M92 | 300W, 350W, 380W, 400W | 8 – 160 | 2000 -3200 | 6000 -12000 |

| JIS G3101 | SS400,SS490 | 8 – 160 8 – 30 | 2000 -3200 150 0-2700 | 6000 -12000 6000 -11800 |

| JIS 33106 | SM490A | 8 – 200 | 2000 -3200 | 6000 -12000 |

| SM400A, SM400B, SM400C SM490A, SM490C, SM490C | 8 – 30 | 1500 -2700 | 6000 -11800 | |

| JIS G3115 | SPV235, SPV315, SPV355 | 8-30 | 1500 -2700 | 6000 -11800 |

| GOST 380-94 | St 3sp | 8 – 160 | 2000 -3200 | 6000 -12000 |

| St 2sp, St 3sp St 5sp | 8 – 25 | 1500 -2700 | 6000 -11800 | |

| St 3ps, St 3sp, St 3Gps, St 4ps, St 4sp | 4 – 50 | 1400 -2500 | 4000 -12000 | |

| GOST 1050-88 | 08, 09, 10, 15, 20, 25, 30, 35, 40, 45, 50 | 8 – 160 4 – 50 | 2000 -3200 1200 -2500 | 6000 -12000 4000 -12000 |

| GOST 4543-71 | 15Mn-50Mn, 15Cr, 20Cr, 30Cr, 35Cr, 40Cr, 45Cr, 30CrMnCu | 4-50 | 1400 -2500 | 12000 |

| GOST 5520-79 | 15K, 20K, 22K, 09Mn2Si, 16MnSi, 10Mn2S11, 17MnSi, 17Mn1Si, 12Cr1MoV, 12CrMo | 8 – 160 4 – 50 | 2000 -3200 1200 -2500 | 6000 -12000 4000 -12000 |

| GOST 5521-93 | A, B, D, E, A32, D32, E32, A36, D36, E36, 27S, D27S, E27S, A40, D40, A408, D4OS, E4OS | 8 – 60* | 2000 -3200 | 6000 -12000 |

| A,B,D,E,A32, D32, A36, D36 | 8 – 25 | 1500 -2700 | 6000 – 11800 | |

| GOST 6713-91 | 16A, 10CrNICu, 15CrSINICu, 15CrSiNiCu-40 | 8 – 60* | 2000 -3200 | 6000 -12000 |

| 16D, 10CrNICu,15CrSiNICu | 4 – 50 | 1200 -2500 | 4000 -12000 |

| CLASSIFICATION, STANDARD | STEEL GRADE | THICKNESS MM (H) | WIDTH MM (A) | LENGTH MM (L) |

|---|---|---|---|---|

| GOST 10885 | 8 – 30 | 1000 -2100 | 6000 -11500 | |

| GOST 14959-79 | 65G | 4 – 50 | 1200 -2500 | 4000 -12000 |

| GOST 19281 | 265, 295, 315, 325, 345, 355, 375, 390, 440 | 8 – 160* 4 – 50 | 2000 – 3200 1200 – 2500 | 6000 – 12000 4000 – 12000 |

| 265, 295, 315, 325, 345, 35 | 8 – 25* | 1500 -2700 | 6000 -11800 | |

| GOST 27772 | C245, C255, C285, C345 | 8 – 25* | 1500 -2700 | 6000 -11800 |

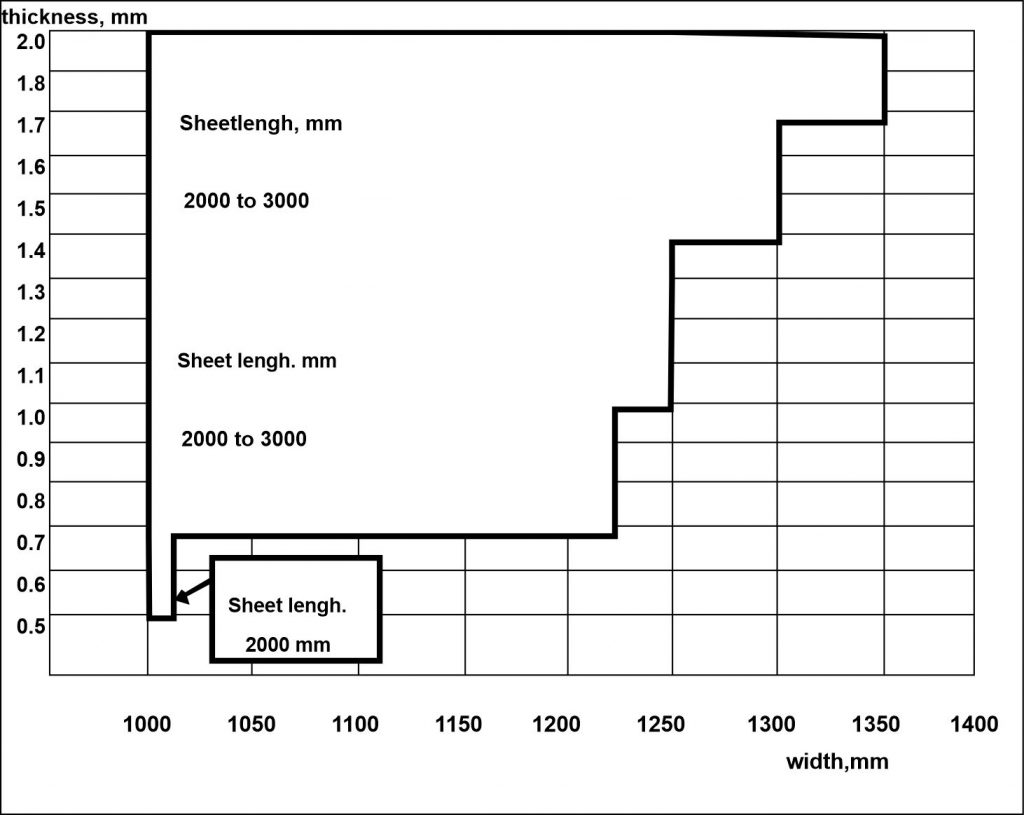

| Standard | Steel grade | Dimensions, mm (GOST 19904, 19281 5) for coils and GOST 16523 6) for sheets) | ||

|---|---|---|---|---|

| Thickness | Width | Length (for sheets) | ||

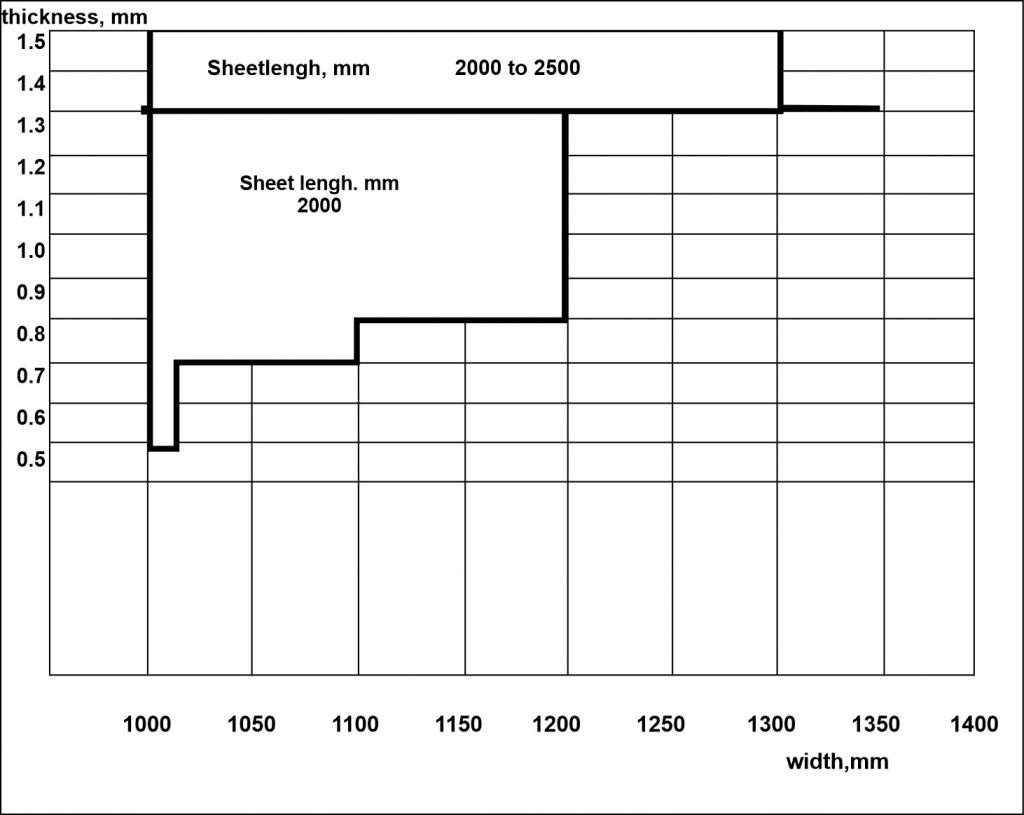

| GOST 380-941) GOST 1050-882) GOST 9045-933) GOST 170664) DIN 1623 p.1 DIN 1623 p.2 DIN 1203 | St 1/2/3 kp/ps/sp 08kp, 08ps, 08, 10kp, l0ps,10, 15kp, 15ps, 15, 20kp, 20ps, 20, 30 08kp, 08YU 09Mn2, 14Mn2, 09Mn2S ST12„UST13, RRST13, ST14 ST37.2, UST37.2, RRST37.2, ST44.3 | 0.5 – 0.7 | 1000 x coil | 2000 |

| 0.7 – 0.8 | 1000 – 1220 x coil | 2000 – 2500 | ||

| 0.8 -1.0 | 1000 – 1220 x coil | |||

| 1.0 – 1.4 | 1000 – 1250 x coil | |||

| 1.4 – 1.7 | 1000 – 1300 x coil | 3000 – 4000 2000 – 4000 2000 – 4000 | ||

| 1.7 – 2.0 | 1000 – 1350 x coil | |||

| 0.5 – 2.0 | 1000 – 1350 x coil | |||

| 0.5 – 2.0 | 1000 – 1350 x coil | |||

| Standard | Steel grade | Dimensions, mm (GOST 19904, 19281 5) for coils and GOST 16523 6) for sheets) | ||

|---|---|---|---|---|

| Thickness | Width | Length (for sheets) | ||

| GOST 380-941) GOST 1050-882) GOST 9045-933) | St 1/2/3 kp/ 08kp, 08kp, 37.24) | 0.5 – 0.7 | 1000 x coil | 2000 |

| 0.7 – 0.8 | 1000 – 1220 x coil | |||

| 0.8 -1.0 | 1000 – 1220 x coil | |||

| 1.0 – 1.3 | 1000 – 1250 x coil | |||

| 1.3 – 1.7 | 1000 – 1300 x coil | 2000 – 2500 | ||

| STANDARD | STEEL GRADE | SIZE | LENGHT | BUNDLE WIEGHT |

|---|---|---|---|---|

| DSTU 3760 -98 | Classes A 300C, A 400C, A 500C | 8 -28 mm | 6000 -12000 mm | up to 5 mt |

| 6, 8 mm | in coils | 550 kgs | ||

| ASTM A615/A615M | Gr. 40, Gr. 60 | ## 3 – 10 | 20′, 30′ and 40′ | Mini-bundles from 1 mt, fixed number of bars |

| CAN/CSA G 30,18 – M 92 | Class 400W | 10M,15M, 20M, 25M, 30M | 6000 -12000 mm | up to 5 mt |

| BS 4449 | Class 460 | 6000 -12000 mm | up to 5 mt |

| STANDARD | STEEL GRADE | SIZE, mm | LD., mm | O.D. mm | H, mm | BUNDLE WEIGHT |

|---|---|---|---|---|---|---|

| GOST 30136-95 | St 1kp, St 3kp, St 3sp GOST 380 -88 | 605 | 8500 – 9000 | 1400 – 1450 | 400 | |

| 5.5 – 14.0 | 850 | 1250 | 1750 | 1100 -2100 kgs | ||

| ASTM A510/A510M | SAE1030 ASTM A568/A568M | 5.5 – 14.0 | 850 | 1250 | 1750 | 1100 -2100 kgs |

| Dimensions, mm | Length, mm | Steel Grade | ||

|---|---|---|---|---|

| H | B | S | ||

| 20 | 20 | 4 | 4000 – 12000 | St 3sp/ps, St 5sp/ps GOST 380 -88 DIN EN 10025* |

| 25 | 25 | 4 | ||

| 32 | 32 | 4 | ||

| 35 | 35 | 4 – 5 | ||

| 40 | 40 | 4 – 5 | ||

| 45 | 45 | 4 – 7 | ||

| 50 | 50 | 4 – 7 | ||

| 55 | 55 | 6 | ||

| 56 | 56 | 5 | ||

| 60 | 60 | 5; 6; 8; | ||

| 63 | 63 | 5; 6 | ||

| 70 | 70 | 6; 7; 9 | ||

| 75 | 75 | 6 – 9 | ||

| 80 | 80 | 6 – 10 | ||

| 90 | 90 | 8 – 9 | ||

| 100 | 100 | 6 – 12 | ||

| 110 | 110 | 8 | ||

| 140 | 140 | 9; 10; 12 | ||

| 160 | 160 | 9; 10; 12, 14, 16,18, 20 | ||

| 180 | 180 | 11, 12 | ||

| 200 | 200 | 12; 13; 14; 16; 20; 25; 30 | ||

| Dimensions, mm | Length, mm | Steel Grade | ||

|---|---|---|---|---|

| 45 | 28 | 4 | ||

| 50 | 32 | 4 | Up to 12000 | St 3sp/ps, St 5sp/ps GOST 380 -88 DIN EN 10025* |

| 56 | 36 | 5 | ||

| 75 | 50 | 4; 5 | ||

| 90 | 56 | 5 | ||

| 100 | 63 | 6:8 | ||

| 160 | 100 | 12; 14 | ||

| 200 | 155 | 11; 12; 14; 16 | ||

| Description of the products | Dimensions | Length, mm | Steel Garden | ||

|---|---|---|---|---|---|

| H, mm | B, mm | S, mm | |||

| Carbon and low – Carbon steel channels | |||||

| # 8U | 80 | 40 | 4.5 | From 4000 to 12000 | St 3kp, St 3ps, St 5ps, St 5sp GOST 380-94DIN EN 10025″ |

| # 10U | 100 | 46 | 4.5 | ||

| # 14U | 140 | 58 | 4.9 | ||

| # 16U | 160 | 64 | 5.0 | ||

| # 18U | 180 | 70 | 5.1 | ||

| # 22U | 220 | 82 | 5.4 | ||

| # 24U | 240 | 90 | 5.6 | ||

| # 27U | 270 | 95 | 6.0 | ||

| # 30U | 300 | 100 | 6.5 | ||

| Channels for r/w car construction | |||||

| # 12U | 180 | 100 | 8.0 | From 4000 to 12000 | St 3kp, St 3ps, St 5ps, St 5sp GOST 380-94 DIN EN 10025″ |

| # 16U | 300 | 85 | 7.5 | ||

| # 18U | 300 | 87 | 9.5 | ||

| # 20U | 300 | 89 | 11.5 | ||

| Channels with parallel flanges | H, mm | B, mm | S, mm | T, mm | Length, mm | Steel grade |

|---|---|---|---|---|---|---|

| # 12U | 120 | 52 | 4.8 | 7.8 | From 4000 to 12000 | St 3ps GOST 380-94 DIN EN 10025* |

| # 16U | 160 | 64 | 5.0 | 8.4 | ||

| # 18U | 180 | 70 | 5.1 | 8.7 | ||

| # 20U | 200 | 76 | 5.2 | 9.0 |

| Profile | Dimensions | Length, mm | Steel grade | ||

|---|---|---|---|---|---|

| N0. | H, mm | B, mm | S, mm | ||

| 14 | 140 | 73 | 4.9 | From 6000 to 12000 | 3kp, 3ps, 3Gsp GOST 380-94) 09G2, 09G2S, 12G2S GOST 19281) |

| 16 | 160 | 81 | 5.0 | ||

| 18 | 180 | 90 | 5.1 | ||

| 20 | 200 | 100 | 5.2 | ||

| 30 | 300 | 135 | 6.5 | ||

| 36 | 360 | 145 | 7.5 | ||

| 45 | 460 | 160 | 9.0 |

| OUTSIDE DIAMETER (MM) | WALL THICKNESS (MM) | LENGTH (M) | |

|---|---|---|---|

| WELDED PIPES | 13.5 – 1422 | 1.0 – 22 | 5-12 |

| SEAMLESS PIPES | 5.0 – 610 | 0.5 – 25 | 4.5 – 11.9 |

| CASING PIPES | 73 – 406.4 | 7.3 -16.66 | 6.5 – 12 |

| BOILER | 16.0 – 433 | 2.0 – 423 | 9 -12 |

| Ordinary Quality Carbon Steel GOST 380.94 | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Steel Grade |

Fraction of total mass of the elements, % | Mechanical properties | ||||||||||||||||||

| C | Mn | Si | S | P | Cr | Ni | Cu | N | As | Gt, MPa | Gv, Mpa | D5 % | KCU .1./cm2 (+20/-20) | |||||||

| No More Then | < 20 mm | 20 – 40 mm | >40 MM | < 20 mm | 20 – 40 mm | >40 MM | 5 – 9 mm | 10 – 25 mm | 26-40 mm | |||||||||||

| St 0 St 1 kp St 1 ps St 1 sp St 2 kp St 2 ps St 2 sp St 3 kp St 3 ps St 3 sp St 3 Gps St 3 Gsp St 4 kp St 4 ps St 4 sp St 5 ps St 5 sp St 5 Gps St 6 ps* St 6 sp* | 0.23 max 0.06-0.12 0.06-0.12 0.06-0.12 0.09-0.15 0.09-0.15 0.09-0.15 0.14-0.22 0.15-0.22 0.15-0.22 0.14-0.22 0.14-0.20 0.18-0.27 0.18-0.27 0.18-0.27 0.29-0.37 0.28-0.37 0.22-0.30 0.39-0.49 0.38-0.49 | 0.25-0.50 0.25-0.50 0.25-0.50 0.25-0.50 0.25-0.50 0.25-0.50 0.30-0.60 0.40-0.65 0.40-0.65 0.80-1.10 0.80-1.10 0.40-0.70 0.40-0.70 0.40-0.70 0.50-0.80 0.50-0.80 0.80-1.20 0.50-0.80 0.50-0.80 | 0.05 max 0.05-0.15 0.15-0.30 0.05 max 0.05-0.15 0.15-0.30 0.05 max 0.06-0.15 0.15-0.30 0.15 max 0.15-0.30 0.05 max 0.05-0.15 0.15-0.30 0.06-0.15 0.15-0.30 0.15 max 0.05-0.15 0.15-0.30 | 0,060 0,050 0,050 0,050 0,050 0,050 0,050 0,050 0,050 0,050 0,050 0,050 0,050 0,050 0,050 0,050 0,050 0,050 0,050 0,050 | 0.070 0.040 0.040 0.040 0,040 0.040 0.040 0040 0,040 0,040 0,040 0.040 0,040 0.040 0,040 0.040 0,040 0,040 0.040 0,040 | 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 | 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 | 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 | 0,01 0,01 0,01 0,01 0,01 0,01 0,01 0,01 0,01 0,01 0,01 0,01 0,01 0,01 0,01 0,01 0,01 0,01 0,01 0,01 | 0,08 0,08 0,08 0,08 0,08 0,08 0,08 0,08 0,08 0,08 0,08 0,08 0,08 0,08 0,08 0,08 0,08 0,08 0,08 0,08 | – – – – 215 225 225 235 245 245 245 255 – 265 285 285 285 285 315 – | – – – – 205 215 215 225 235 235 235 245 – 255 255 275 275 275 306 – | —-195 205 205 215 225 225 225 –245 245 265 265 265 295 – | 300 min – – – 320-410 330-430 330-430 380-480 370-480 370-480 370-480 390-570 – 410-530 410-530 490-630 490-630 450-590 590min – | 23 – – – 33 32 32 27 26 26 20 23 – 24 24 20 20 20 15 – | 22 – – – 32 31 31 20 25 25 25 24 – 23 23 19 19 19 14 – | 20 – – – 30 29 29 24 23 23 23 – – 21 21 17 17 17 12 – | – – – – – – – – 78/39 78/39 78/39 78/39 – 78/- 78/- – – – – – | – – – – – – – – 69/29 69/29 69/29 69/29 – 59/- 59/- – – – – – | – – – – – – – – 49/- 49/- 49/- 49/29 – 39/- 39/- – – – – – |

| Limiting deviations for steel rolled products | |||||

| Steel | Elements | ||||

Rimming killed and semikilled | C +/-0.03 +0.03/-0.02 | Mn +0.051-0.04 +0.051-0.03 | SI – +0.03/-0.02 | S +0.006 +0.005 | P N +0.006 +0.002 +0.005 +0.002 |

| Calibrated Sections With the Special Surface Finishing of the Carbon Quality Structural Steel GOST 1050-88 | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Steel grade | Fraction of total mass of the elements, % | Mechanical properties | ||||||||||||

| C | Mn | SI | S | P | Cr | NI | Cu | Gt. MPa | Gv, MPa | d5.% | Y, % | KCU J/c m2 | Hb for hot-rolled | |

| No More then | ||||||||||||||

| 05kp 08kp 08ps 08 10kp 10ps 10 11kp 15kp 15ps 15 18kp 2Okp 20ps 20 25 30 35 40 45 50 55 68(55nn) 60 | 0 06 max 0.05-0.12 0.05-0.11 0.05-0.12 0.07-0.14 0.07-0.14 0.07-0.14 0.05-0.12 0.12-0.19 0.12-0.19 0.12-0.19 0.12-0.20 0.17-0.24 0.17-0.24 0.17-0.24 0.22-0.30 0.27-0.35 0.32-0.40 0.37-0.45 0.42-0.50 0.47-0.55 0.52-0.60 0.55-0.63 0.57-0.65 | 0.40 max 0.25-0.50 0.35-0.65 0.35-0.66 0.25-0.50 0.35-0.65 0.35-0.65 0.30-0.50 0.25-0.60 0.35-0.66 0.35-0.65 0.30-0.50 0.25-0.50 035.065 0.35-0.65 0.50-0.80 0.50-0.80 0.50-0.80 0.50-0.80 0.50-0.80 0 50-0 80 0.50-0.80 0 20 max 0.50-0.80 | 0.03 max 0.03 max 0.05-0.17 0.17-0.37 0.07 max 0.05-0.17 0.17-0.37 0.06 max 0.07 max 0.05-0.17 0.17-0.37 0.06 max 0.07 max 0.05-0.17 0.17-0.37 0.17-0.37 0.17-0.37 0.17-0.37 0.17-0.37 0.17-0.37 0.17-0.37 0.17-0.37 0.10-0.30 0.17-0.37 | 0,040 0,040 0,040 0,040 0,040 0,040 0,040 0,040 0,040 0,040 0,040 0,040 0,040 0,040 0,040 0,040 0,040 0,040 0,040 0.040 0,040 0,040 0,040 0,040 | 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 | 0.10 0,10 0,10 0,10 0,15 0,15 0,15 0,15 0,25 0,25 0,25 0,15 0,25 0,25 0,25 0,25 0,25 0,25 0,25 0,25 0,25 0,25 0,15 0,25 | 0,030 0,030 0,030 0,030 0,030 0,030 0,030 0,030 0,030 0,030 0,030 0,030 0,030 0,030 0,030 0,030 0,030 0,030 0,030 0,030 0,030 0,030 0,030 0,030 | 0,030 0,030 0,030 0,030 0,030 0,030 0,030 0,020 0,030 0,030 0,030 0,020 0,030 0,030 0,030 0,030 0,030 0,030 0,030 0,030 0,030 0,030 0,030 0,030 | 196 205 225 245 275 295 315 335 355 375 380 315 400 | 320 330 370 410 450 490 530 570 600 630 650 600 680 | 33 31 27 25 30 21 20 19 16 14 13 12 12 | 60 55 55 55 50 50 45 45 40 40 35 28 35 | 88 78 69 59 49 38 | 131 143 149 163 170 179 207 217 229 241 255 255 255 |

| Permisible dIviations, % | Elements | |||

| C | Mn | SI for killed steel | P | |

| +/- 0.01 | +0.05/-0.04 | +/-0.02 | +0.005 | |

| Cold-rolled thin sheets of low-carbon steel for cold stamping GOST 9045-93 | |||||||||

| Steel Grade | Fraction of total mass of the elements, % | ||||||||

| C | Mn | S | P | Si | Cr | Ni | Cu | Al | |

| not more than | |||||||||

| 08Yu 08ps 08kp | 0,07 0,09 0,10 | 0,35 0,45 0,40 | 0,025 0,030 0,030 | 0,020 0,025 0,025 | 0,03 0,04 0,03 | 03 0,10 0,10 | 0,06 0,10 0,10 | 0,06 0,15 0,15 | 0.02-0.07 |

| Ability for Stamping | Yield point, N/mm2 | Tensile strength, N/mm2 | Elongation, % | Hadness, not more | |||||

| < 0.7 mm | fm0.7 to 1.5 mm incl. | fm 1.5 to 2.0 mm incl. | fm 2.0 to 3.9 mm incl. | fm 0.5 to 0.8 mm incl. | fm 0.8 1.7 mm incl. | fm 1.7 to 2.0 mm incl. | |||

| OSV SV VG VOSV VOSV-T | 195 205 – 185 175 | 250-350 250-380 250-390 250-350 250-320 | 34 32 26 38 40 | 36 34 28 40 42 | 40 38 29 42 44 | 42 40 30 – – | 76 78 – 76 75 | 51 53 – 51 45 | 46 48 – 46 43 |

| Group of strength | Mechanical properties | Steel grades | ||

| Tensile strength Gv =>, N/mm 2 | elongation d4 =>, % | |||

| plate thickness | ||||

| 2.00 mm | > 2.0 mm | |||

| OK 300 V | 300 – 480 | 21 | 23 | St1kp, St1ps, St1sp, St2kp, St2ps, St2sp, |

| OK 360 V | 360 – 530 | 20 | 22 | St3kp, St3ps, St3sp, |

| OK 400 V | 400 – 680 | 17 | 19 | St4kp, St4ps, St4sp, St5ps, St5sp, |

| K 260 V | 260 – 380 | 25 | 28 | 08 kp |

| K 270 V | 270 – 410 | 24 | 26 | 08 ps, 08, 10 kp, 10 ps, 10 |

| K 310 V | 310 – 440 | 23 | 25 | 15 kp, 15 ps |

| K 330 V K 350 V | 330 – 460 350 – 500 | 23 22 | 24 23 | 15, 20 kp 20 ps, 20 |

| K 390 V | 390 – 590 | 19 | 20 | 25, 30 |

| K 490 V | 490 – 720 | 12 | 13 | 35, 40, 45 |

| Steel Grades | Mechanical properties | Chemical Composition | ||

| tensile strength Gv=>, N/mm2 | elongation, d4 =>, % | yield point, Gt =>, N/mm2 | ||

| 09Mn2 12MnSi | 441 461 490 461 490 470 490 | 20 22 20 17 20 20 17 | 295 315 325 – 345 345 – | GOST 19281 |

| Steel Grades | Chemical composition , % | ||||||||

| C | Mn | Si | Cr | NI | Cu | Al | S | P | |

| not more than | |||||||||

| D32 A32 A V D | <= 0.18 <= 0.18 <= 0.22 <= 0.21 <= 0.21 | 0.9-1.6 0.9-1.6 0.4-1.0 0.4-1.1 0.6-1.4 | 0.15-0.50 0.15-0.50 0.15-0.37 0.15-0.37 0.15-0.37 | <= 0.20 <= 0.20 – – – | <= 0.40 <= 0.40 – – – | <= 0.35 <= 0.35 <= 0.35 – – – | <= 0.06 <= 0.06 – <= 0.06 0.015-0.06 | 0,035 0,035 0,04 0,04 0,04 | 0,035 0,035 0,04 0,04 0,04 |

| Steel Grades | Mechanical properties | ||||||

| tensile strength Gv =>, N/mm2 | elongation d4 =>, % | yield point Gt =>, N/mm2 | |||||

| 0 | -10 | -20 | -40 | ||||

| A V D A32 D32 A36 D36 | 400-490 400-490 400-490 470-590 470-590 490-620 490-620 | 22 22 22 22 22 21 21 | 235 235 235 215 215 355 355 | – 27 (2.8) 27 (2.8) 31 (3.2) 31 (3.2) 34 (3.5) 34 (3.5) | 27 (2.8) 27 (2.8) – – – – | – – – 31 (3.2) 31 (3.2) 34 (3.5) 34 (3.5) | – 27 (2.8) 27 (2.8) 31 (3.2) 31 (3.2) 34 (3.5) 34 (3.5) |

| teel grades | Chemical composition, % | ||||||||

| C | Mn | Si | Cr | NI | Cu | Al | S | P | |

| not more than | |||||||||

09Mn2Si 09Mn2 09Mn2Cu 12MnSi 16MnSi 17MnSi 17Mn1 Si 14Mn2 10Mn2Si1 10Mn2Si1 Cu 1 OCrSiNiCu | <= 0.12 <= 0.12 <= 0.12 0.09-0.15 0.12-0.18 0.14-0.20 0.15-0.20 0.12-0.18 <= 0.12 <= 0.12 <= 0.12 | 1.3-1.7 1.4-1.8 1.4-1.8 0.8-1.2 0.9-1.2 1.0-1.4 1.15-1.6 1.2-1.6 1.3-1.65 1.3-1.65 0.5-0.8 | 0.5-0.8 0.17-0.37 0.17-0.37 0.5-0.8 0.4-0.7 0.4-0.6 0.4-0.6 0.17-0.37 0.8-1.1 0.8-1.1 0.8-1.1 | <= 0.30 <= 0.30 <= 0.30 <= 0.30 <= 0.30 <= 0.30 <= 0.30 <= 0.30 <= 0.30 <= 0.30 0.6-0.9 | <= 0.30 <= 0.30 <= 0.30 <= 0.30 <= 0.30 <= 0.30 <= 0.30 <= 0.30 <= 0.30 <= 0.30 0.5-0.8 | <= 0.30 <= 0.30 0.15-0.30 <= 0.30 <= 0.30 <= 0.30 <= 0.30 <= 0.30 <= 0.30 0.15-0.30 0.4-0.6 | – – – – – – – – – – – | 0,04 0,04 0,04 0,04 0,04 0,04 0,04 0,04 0,04 0,04 0,04 | 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 |

| of Strength | Mechanical properties | Steel Grades | ||||

| tensile strength Gv N/mm2 | elongation d4 To | yield point Gt N/mm2 | ||||

tensile strength Gv =>, N/mm2 | elongation d4 % | yield point Gt =>, N/mm2 | <= 10 mm | <= 20 mm | > 20 mm | |

| 265 295 315 325 345 345 | 430 430 450 450 490 490 | 21 21 21 21 21 21 21 | 265 295 315 325 345 355 355 | St 3 sp 09G2 12GS 16GS 09G2S 17GS 10XNDP 10G2S1 14XGS 17G1S | St 3 sp 09G2′ 16GS* 09G2S 15GF 17G1S – – 15GF ‘ | 09G2S 09G2 1002S1 14G2 |

| des (Class of hardness) Steel | Mechanical properties of plates | ||||||||

| tensile strength Gv a, N/mm2 | elongation d4 =>, % | yield point Gt ”, N/mm2 | |||||||

| thickness of plates | |||||||||

| <= 10 mm | <= 20 mm | > 20 mm | <= 10 mm | <= 20 mm | > 20 mm | <= 10 mm | <= 20 mm | > 20 mm | |

| S 235 S 245 S 255 S 275 S 285 S 345 S 355 S 375 | 360 370 380 390 390 490 500 510 | 360 370 370 390 380 470 490 500 | 370 460 | 26 25 25 24 24 21 20 20 | 26 25 25 * 24 23 21’* 20 20 | – 25 – 21 | 235 245 245 275 265 325 355 375 | 235 245 245 275 265 325 355 375 | 235 245 – 305 |

| Class of hardness | Steel grades | Chemical composition,% (max or width range) | |||||||

| C | Mn | Si | S | P | Cr | Ni | Cu | ||

| S 235 S 245 S 255 S 275 S 285 S 345 S 355 S 375 | 3kp 3ps 3sp, 3Gps 3sp, 3Gps 3sp, 3Gps 3ps,09G2S, 12G2S 12G2S 12G2S | 0,22 0,22 0 22 0,22 0,22 0,15 0,15 0,15 | 0.30-0.60 0,65 0,65 0.80-1.10 0.80-1.10 1.30-1.70 1.30-1.70 1.30-1.70 | 0,05 0.05-0.15 0.15-0.30 0,30 0,30 0,80 0,80 0,80 | 0,050 0,050 0,050 0,050 0,040 0,040 0,040 | 0,040 0,040 0,040 0,040 0,040 0,040 0,035 0,035 0,035 | 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 | 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 | 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 |

| American Standards | |||||||||||||||||||

| Standards | Steel Grade | Plate thickness, mm | Fraction of total mass ol the elements % | Mechanical properties | |||||||||||||||

| C | Mn | Si | S | I | Cu | Cr | V | Nb | Ni | Mo | A1 | T1 | Gt, Mpa | Gn, Mpa | |||||

| no more the or within | 8″ 200mm | 2″50mm | |||||||||||||||||

| ASTM A36/36M 35 | 36 | o 20 Incl 20-40Incl 40-60Incl 65-100Incl over 100 | 0.25 0.25 0.26 0.27 0.29 | 0.80-1.20 0.80-1.20 0.85-1.20 0.85-1.20 | 0,40 0,40 0.15-0.40 0.15-0.40 0.15-0.40 | 0,050 0,050 0,050 0,050 0,050 | 0,040 0,040 0,040 0,040 0,040 | min 0.20* min 0.20* min 0.20* min 0.20* min 0.20* | Per 0.01 % of decrease of carbon content increase of Mn by 0.06% is permited but not more than 1.35% when Cu is provided | 400-550 400-550 400-550 400-550 400-550 | 250 250 250 250 250 | 20 20 20 20 20 | 23 23 23 23 23 | ||||||

| A131/131M | A B D E CS DS AH/DH/EH 32 AH/DH/EH 36 | 0,23 0,21 0,21 0,18 0,16 016 0,18 | 2.5xCmin 0.80-1.10 0.70-1.35 0.70-1.35 1.00-1.35 1.00-1.35 0.9-1.60 0.9-1.60 | 0,35 0.10-0.35 0.10-0.35 0.10-0.35 0.10-0.35 0.10-0.50 0.10-0.50 | 0,040 0,040 0,040 0,040 0,040 0,040 0,040 0,040 | 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 | 0,05 0,05 | 0,25 0,25 | * * * * * * | * * * * 0,100 0,100 | each heat should contain min 0.02% of Nb or min 0.05% V and if V + Al , than V shouldn’t exeed 0,03% and soluable in axid Al should be 0.015%. | 400-490 400-490 400-490 400-490 400-490 400-490 470-585 490-620 | 235 235 235 235 235 235 315 360 | 21 21 21 21 21 21 19 19 | 24 24 24 24 24 24 22 22 | ||||

| 0,40 0,40 | 0,08 0,08 | min 0.02 min 0.02 | |||||||||||||||||

| A283/283M | A B C D | 0,14 0,14 0,24 0,27 | 0.90 0.90 0.90 0.90 | 0,40 0,40 0,40 0,40 | 0,040 0,040 0,040 0,040 | 0,035 0,035 0,035 0,035 | min 0.20* min 0.20* min 0.20* min 0.20* | * if agreed in order Si 0.15-0.40% for plates over 40 mm | 310-415 345-450 380-515 415-550 | 165 185 205 230 | 25 23 22 18 | 28 26 25 21 | |||||||

| A510/510M | 1008 | 0,10 | 0,30-0,50 | 0,050 | 0,040 | ||||||||||||||

| A515/515M | 60 65 70 | to 25 25-50 to 25 25-50 to 25 25-50 | 0,24 0,27 0,28 0,31 0,31 0,33 | 0,90 0,90 1,20 | 0.15-0.40 0.15-0.40 0.15-0.40 | 0,035 0,035 0,035 | 0,035 0,035 0,035 | 415-550 450-585 485-620 | 220 240 260 | 21 19 17 | 25 23 21 | ||||||||

| A516/516M | 55 60 65 70 | to 12.5 12.5-50 to 12.5 12.5-50 to 12.5 12.5-50 to 12.5 12.5-50 | 0,18 0,21 0,21 0,23 0,24 0,26 0,27 0,28 | 0.60-0.90 0.60-1.20 0.60-0.90 0.85-1.20 0.85-1.20 0.85-1.20 | 0.15-0.40 0.15-0.40 0.15-0.40 0.15-0.40 | 0,035 0,035 0,035 0,035 | 0,035 0,035 0,035 0,035 | 380-515 415-550 450-585 485-620 | 205 220 240 260 | 23 21 19 17 | 27 25 23 21 | ||||||||

| A537/537M | 1,2,3, Class 1 Class2 | to 40 incl over 40 to 65 incl 65-100 to 65 incl 65-100 | 0,24 0,24 | 0.70-1.35 1.00-1.60 | 0.15-0.50 0.15-0.50 | 0,035 0,35 | 0,035 0,035 | 0,35 0,35 | 0,25 0,25 | 0,25 0,25 | 0,08 0,08 | 485-620 450-585 550-690 515-655 550-690 | 345 310 415 380 380 | 18 18 18 18 18 | 22 22 22 22 22 | ||||

| American Standards | |||||||||||||||||||

| Standards | Steel Grade | Plate thickness, mm | Fraction of total mass ol the elements % | Mechanical properties | |||||||||||||||

| C | Mn | Si | S | I | Cu | Cr | V | Nb | Ni | Mo | A1 | T1 | Gt, Mpa | Gn, Mpa | |||||

| no more the or within | 8″ 200mm | 2″50mm | |||||||||||||||||

| ASTM A36/36M 35 | 36 | o 20 Incl 20-40Incl 40-60Incl 65-100Incl over 100 | 0.25 0.25 0.26 0.27 0.29 | 0.80-1.20 0.80-1.20 0.85-1.20 0.85-1.20 | 0,40 0,40 0.15-0.40 0.15-0.40 0.15-0.40 | 0,050 0,050 0,050 0,050 0,050 | 0,040 0,040 0,040 0,040 0,040 | min 0.20* min 0.20* min 0.20* min 0.20* min 0.20* | Per 0.01 % of decrease of carbon content increase of Mn by 0.06% is permited but not more than 1.35% when Cu is provided | 400-550 400-550 400-550 400-550 400-550 | 250 250 250 250 250 | 20 20 20 20 20 | 23 23 23 23 23 | ||||||

| A131/131M | A B D E CS DS AH/DH/EH 32 AH/DH/EH 36 | 0,23 0,21 0,21 0,18 0,16 016 0,18 | 2.5xCmin 0.80-1.10 0.70-1.35 0.70-1.35 1.00-1.35 1.00-1.35 0.9-1.60 0.9-1.60 | 0,35 0.10-0.35 0.10-0.35 0.10-0.35 0.10-0.35 0.10-0.50 0.10-0.50 | 0,040 0,040 0,040 0,040 0,040 0,040 0,040 0,040 | 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 | 0,05 0,05 | 0,25 0,25 | * * * * * * | * * * * 0,100 0,100 | each heat should contain min 0.02% of Nb or min 0.05% V and if V + Al , than V shouldn’t exeed 0,03% and soluable in axid Al should be 0.015%. | 400-490 400-490 400-490 400-490 400-490 400-490 470-585 490-620 | 235 235 235 235 235 235 315 360 | 21 21 21 21 21 21 19 19 | 24 24 24 24 24 24 22 22 | ||||

| 0,40 0,40 | 0,08 0,08 | min 0.02 min 0.02 | |||||||||||||||||

| A283/283M | A B C D | 0,14 0,14 0,24 0,27 | 0.90 0.90 0.90 0.90 | 0,40 0,40 0,40 0,40 | 0,040 0,040 0,040 0,040 | 0,035 0,035 0,035 0,035 | min 0.20* min 0.20* min 0.20* min 0.20* | * if agreed in order Si 0.15-0.40% for plates over 40 mm | 310-415 345-450 380-515 415-550 | 165 185 205 230 | 25 23 22 18 | 28 26 25 21 | |||||||

| A510/510M | 1008 | 0,10 | 0,30-0,50 | 0,050 | 0,040 | ||||||||||||||

| A515/515M | 60 65 70 | to 25 25-50 to 25 25-50 to 25 25-50 | 0,24 0,27 0,28 0,31 0,31 0,33 | 0,90 0,90 1,20 | 0.15-0.40 0.15-0.40 0.15-0.40 | 0,035 0,035 0,035 | 0,035 0,035 0,035 | 415-550 450-585 485-620 | 220 240 260 | 21 19 17 | 25 23 21 | ||||||||

| A516/516M | 55 60 65 70 | to 12.5 12.5-50 to 12.5 12.5-50 to 12.5 12.5-50 to 12.5 12.5-50 | 0,18 0,21 0,21 0,23 0,24 0,26 0,27 0,28 | 0.60-0.90 0.60-1.20 0.60-0.90 0.85-1.20 0.85-1.20 0.85-1.20 | 0.15-0.40 0.15-0.40 0.15-0.40 0.15-0.40 | 0,035 0,035 0,035 0,035 | 0,035 0,035 0,035 0,035 | 380-515 415-550 450-585 485-620 | 205 220 240 260 | 23 21 19 17 | 27 25 23 21 | ||||||||

| A537/537M | 1,2,3, Class 1 Class2 | to 40 incl over 40 to 65 incl 65-100 to 65 incl 65-100 | 0,24 0,24 | 0.70-1.35 1.00-1.60 | 0.15-0.50 0.15-0.50 | 0,035 0,35 | 0,035 0,035 | 0,35 0,35 | 0,25 0,25 | 0,25 0,25 | 0,08 0,08 | 485-620 450-585 550-690 515-655 550-690 | 345 310 415 380 380 | 18 18 18 18 18 | 22 22 22 22 22 | ||||

| Standards | Steel Grade | Plate thickness, mm | Fraction of total mass ol the elements % | Mechanical properties | |||||||||||||||

| C | Mn | Si | S | I | Cu | Cr | V | Nb | Ni | Mo | A1 | T1 | Gt, Mpa | Gn, Mpa | d5, % | ||||

| no more the or within | 8″ 200mm | 2″ 50mm | |||||||||||||||||

| A569/569M | 1.2-6.0 | 0.25 | 0.90 | 0.040 | 0.035 | 0.20* | 0.15 | 0.008 | 0.008 | 0.20 | 0.06 | SHOULD PASS FALT BAND TEST | |||||||

| A570/570M | 30,33,36,40, 45,50,55 | 0.65-6.0 0.65-6.0 | 0.25 0.25 | 0.90 1.35 | 0.040 0.040 | 0.035 0.035 | 0.20* 0.20* | 0.15 0.15 | 0.008 0.008 | 0.008 0.008 | 0.20 0.20 | 0.06 0.06 | |||||||

| A572/572M | 42 50 60 65 | 32 13-22 <12 | 0.21 0.23 0.26 0.23 0.26 | 1.35 1.35 1.35 1.35 1.35 | 0.4 0.4 0.4 0.4 | 0.050 0.050 0.050 0.050 | 0.040 0.040 0.040 0.040 | 415 450 520 550 | 290 345 405 405 | 20 18 16 15 | 24 21 18 17 | ||||||||

| Type 1 – Nb 0.005-0.05%; tYPE2-V 0.01-0.15% tYPE3 -Nb(0.05max) + V-0.02-0.15; Type4 – Nb+V – 00.015% max | |||||||||||||||||||

| A573/573M | 58 65 70 | to 13 incl 13-40 to 13 incl 13-40 to 13 incl 13-40 | 0,23 0,23 0,24 0,26 0,27 0,28 | 0.60-0.90* 0.60-0.90* 0.85-1.20 0.85-1.20 0.85-1.20 0.85-1.20 | 0.10-0.35 0.10-0.35 0.15-0.40 0.15-0.40 0.15-0.40 0.15-0.40 | 0.040 0.040 0.040 0.040 0.040 0.040 | 0.035 0.035 0.035 0.035 0.035 0.035 | ‘Upper limit of Mn content may be exeeded, but in laddle analysis content of C + 1/6 Mn should not exeed 0.40% | 400-490 400-490 450-530 450-530 485-620 485-620 | 220 220 240 240 290 290 | 19 19 18 18 16 16 | 22 22 21 21 19 19 | |||||||

| A588/588M | A B C D K | 0.19 0.2 0.15 0.10-0.20 0.17 | 0.80-125 0.75-1.35 0.80-1.35 0.75-1.25 0.50-1.20 | 0.30-0.65 0.15-0.50 0.15-0.40 0.15-0.90 0.25-0.50 | 0.050 0.050 0.050 0.050 0.050 | 0.040 0.040 0.040 0.040 0.040 | 0.40-0.65 0.25-0.40 0.25-0.50 0,30 0.30-0.50 | 0.40-0.65 0.40-0.70 0.30-0.50 0.50-0.90 0.40-0.70 | 0.02-0.10 0.01-0.10 0.01-0.10 | 0.040 0,050 | 0,40 0,50 0.25-0.5 0 0,40 | 0,10 | 485 485 485 485 485 | 345 345 345 345 345 | 16 16 16 16 16 | 19 19 19 19 19 | |||

| ABS | AB/A AB/B AB/E AB/D AH/DH/EH 32 AHDH/EH 36 | 0.09-0.14 0.09-0.14 0.09-0.14 0.09-0.14 0.18 0.18 | 0.6-0.9 0.8-1.10 0.8-1.10 0.6-0.90 0.90-1.60 0.90-1.6 | 0.17-0.35 0.17-0.35 0.17-0.35 0.17-0.35 0.10-0.50 0.10-0.50 | 0,035 0,035 0,035 0,035 0,035 0,035 | 0,035 0,035 0,035 0,035 0,035 0,035 | 0,30 0,30 0,30 0,35 0,35 | 0,30 0,30 0,30 0,20 0,20 | 0.05-0.100 0.05-0.100 | 0,30 0,30 0,30 0,40 0,40 | 0,08 0,08 | 0,02 0,015 0,015 | 0,02 0,02 | 400-520 400-520 400-520 400-520 440-590 490-620 | 235 235 235 235 315 365 | 22 22 22 22 22 21 | 24 24 24 24 22 22 | ||

| German Standards | |||||||||||||||||||

| Standard | Steel grade | Plate thick, mm | |||||||||||||||||

| C | Mn | Si | S | P | Al | Ti | Mo | N | Nb | V | Gv. MPo 400-520 400-520 400-520 400-520 440-570 440-570 440-570 510-660 510-660 490-630 | Gt. MPo | d5.% | ||||||

| no more than or with in | <16 incl. | 16-40 mm Incl | 40-63 mm incl | 3-40mm incl | 40-63 mm incl | ||||||||||||||

| German Lloyd’s Register | GLA < 50 GLB < 50 GLE <50 GLD < 50 GLA32 < 50 GLD32 <50 GLE32 <50 GLA40 < 50 GLD < 50 GLAND/E36 <50 | 0,09-0.14 0,09-0.14 0,09-0.14 0,09-0.14 1.20-1.60 1.20-1.60 1.20-1.60 1.20-1.60 1.20-1.60 0.14-0.18 | 0.60-0.90 0.80.1.10 0.80-1 10 0.60-0.90 1.20-1.60 1.20-1.60 1.20-1.60 1.20-1.60 1.20-1.60 1.20-1.60 | 0,17-0,35 0,17-0,35 0,10-0,25 0,17-0,35 0,17-0,50 0,50 0,50 0,50 0,50 0,50 | 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 | 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 | 0,020 0,020 0,020 0,020 0,020 0,020 0,020 0,020 | 0,03 0,03 0,02 0,02 0,02 | 0,08 0,08 0,08 | 0,02-0,05 0,02-0,05 0,02-0,05 0,02-0,05 0,02-0,05 0,02-0,05 | 0,05-0,10 0,05-0,10 0,05-0,10 0,05-0,10 0,05-0,10 0,05-0,10 | 235 235 235 235 315 315 315 390 390 355 | 22 22 22 22 22 22 22 20 20 21 | ||||||

| Din 17100 | St37-2 RSt37-2 St37-2 St44-3 St52-3 St50-2 St60-2 | 0,12-0,17 0,12-0,17 0,12-0,17 0,14-0,18 0.15-0,20 0,28-0,37 0,28-0,37 | 0,40-0,60 0.40-0.60 0.40-0.60 0.45-0.65 1.20-1.60 1.50-0.80 0.50-0.80 | 0,10 0.15-0.30 0.15-0.30 0.17-0.37 0.35-0.55 0.15-0.35 | 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 | 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 | 0,10 0,020 0,020 0,020 0,020 0,020 0.020 | 340-470 340-470 340-470 410-540 490-630 470-670 570-710 | 235 235 253 275 355 295 335 | 225 225 225 265 345 285 325 | 215 215 215 215 335 275 315 | 26/24 26/24 26/24 22/20 22/20 20/18 16/14 | 25/23 25/23 25/23 21/19 21/19 19/17 15/13 | ||||||

| Din 17207 | SPH235 SPH265 SPHL275 | 0,16 0,20 0,20 | 0.40-1.20 0.50-1.50 0.50-1.50 | 0,35 0,40 0,40 | 0,030 0,030 0,025 | 0,035 0,030 0,035 | 0,020 >0,020 >0,020 | 340-480 410-530 390-510 | 235 265 275 | 225 255 265 | 215 245 255 | 26 22 24 | 25 22 24 | ||||||

| DIN EN | S235JR S235HRG2 S265JO S235J2G3 S235J2G4 S275JR S275JO S275J2G3 S275J2G4 S355JR S355JO S355J2G3 S355J2G4 | 0,17 1,40 0,17 1,40 0,17 1,40 0,17 1,40 0,17 1,40 0.21 1,50 0,18 1,50 0,18 1,50 0,18 1,50 0,24 1,60 0,20 1,60 0,20 1,60 0,20 1,60 0,20 1,60 0,20 1,60 | 0.55 0.55 0.55 0.55 0.55 0.55 | 0,045 0,045 0,040 0,035 0,035 0,045 0,040 0,035 0,035 0,045 0,040 0,035 0,035 0,035 0,035 | 0,045 0,045 0,040 0,035 0,035 0,045 0,040 0,035 0,035 0,045 0,040 0,035 0,035 0,035 0,035 | 0,009 0,009 0,009 0,009 0,009 0,009 0,009 | 340-470 340-470 340-470 340-470 340-470 410-560 410-560 410-560 410-560 490-630 490-630 490-630 490-630 490-630 490-630 | 235 235 235 235 235 275 275 275 275 355 355 355 355 355 355 | 225 225 225 225 225 265 265 265 265 345 345 345 345 345 | 215 215 215 215 255 255 255 255 335 335 335 335 335 | 24 24 24 24 24 20 20 20 20 20 20 20 20 20 20 20 | 23 23 23 23 23 19 19 19 19 19 19 19 19 19 19 | |||||||

| German Standards | |||||||||||||||||||

| Standard | Steel grade | Plate thick, mm | |||||||||||||||||

| C | Mn | Si | S | P | Al | Ti | Mo | N | Nb | V | Gv. MPo 400-520 400-520 400-520 400-520 440-570 440-570 440-570 510-660 510-660 490-630 | Gt. MPo | d5.% | ||||||

| no more than or with in | <16 incl. | 16-40 mm Incl | 40-63 mm incl | 3-40mm incl | 40-63 mm incl | ||||||||||||||

| German Lloyd’s Register | GLA < 50 GLB < 50 GLE <50 GLD < 50 GLA32 < 50 GLD32 <50 GLE32 <50 GLA40 < 50 GLD < 50 GLAND/E36 <50 | 0,09-0.14 0,09-0.14 0,09-0.14 0,09-0.14 1.20-1.60 1.20-1.60 1.20-1.60 1.20-1.60 1.20-1.60 0.14-0.18 | 0.60-0.90 0.80.1.10 0.80-1 10 0.60-0.90 1.20-1.60 1.20-1.60 1.20-1.60 1.20-1.60 1.20-1.60 1.20-1.60 | 0,17-0,35 0,17-0,35 0,10-0,25 0,17-0,35 0,17-0,50 0,50 0,50 0,50 0,50 0,50 | 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 | 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 | 0,020 0,020 0,020 0,020 0,020 0,020 0,020 0,020 | 0,03 0,03 0,02 0,02 0,02 | 0,08 0,08 0,08 | 0,02-0,05 0,02-0,05 0,02-0,05 0,02-0,05 0,02-0,05 0,02-0,05 | 0,05-0,10 0,05-0,10 0,05-0,10 0,05-0,10 0,05-0,10 0,05-0,10 | 235 235 235 235 315 315 315 390 390 355 | 22 22 22 22 22 22 22 20 20 21 | ||||||

| Din 17100 | St37-2 RSt37-2 St37-2 St44-3 St52-3 St50-2 St60-2 | 0,12-0,17 0,12-0,17 0,12-0,17 0,14-0,18 0.15-0,20 0,28-0,37 0,28-0,37 | 0,40-0,60 0.40-0.60 0.40-0.60 0.45-0.65 1.20-1.60 1.50-0.80 0.50-0.80 | 0,10 0.15-0.30 0.15-0.30 0.17-0.37 0.35-0.55 0.15-0.35 | 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 | 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 | 0,10 0,020 0,020 0,020 0,020 0,020 0.020 | 340-470 340-470 340-470 410-540 490-630 470-670 570-710 | 235 235 253 275 355 295 335 | 225 225 225 265 345 285 325 | 215 215 215 215 335 275 315 | 26/24 26/24 26/24 22/20 22/20 20/18 16/14 | 25/23 25/23 25/23 21/19 21/19 19/17 15/13 | ||||||

| Din 17207 | SPH235 SPH265 SPHL275 | 0,16 0,20 0,20 | 0.40-1.20 0.50-1.50 0.50-1.50 | 0,35 0,40 0,40 | 0,030 0,030 0,025 | 0,035 0,030 0,035 | 0,020 >0,020 >0,020 | 340-480 410-530 390-510 | 235 265 275 | 225 255 265 | 215 245 255 | 26 22 24 | 25 22 24 | ||||||

| DIN EN | S235JR S235HRG2 S265JO S235J2G3 S235J2G4 S275JR S275JO S275J2G3 S275J2G4 S355JR S355JO S355J2G3 S355J2G4 S355K2G3 S355K2G4 | 0,17 1,40 0,17 1,40 0,17 1,40 0,17 1,40 0,17 1,40 0.21 1,50 0,18 1,50 0,18 1,50 0,18 1,50 0,24 1,60 0,20 1,60 0,20 1,60 0,20 1,60 0,20 1,60 0,20 1,60 | 0.55 0.55 0.55 0.55 0.55 0.55 | 0,045 0,045 0,040 0,035 0,035 0,045 0,040 0,035 0,035 0,045 0,040 0,035 0,035 0,035 0,035 | 0,045 0,045 0,040 0,035 0,035 0,045 0,040 0,035 0,035 0,045 0,040 0,035 0,035 0,035 0,035 | 0,009 0,009 0,009 0,009 0,009 0,009 0,009 | 340-470 340-470 340-470 340-470 340-470 410-560 410-560 410-560 410-560 490-630 490-630 490-630 490-630 490-630 490-630 | 235 235 235 235 235 275 275 275 275 355 355 355 355 355 355 | 225 225 225 225 225 265 265 265 265 345 345 345 345 345 345 | 215 215 215 215 255 255 255 255 335 335 335 335 335 335 | 24 24 24 24 24 20 20 20 20 20 20 20 20 20 20 | 23 23 23 23 23 19 19 19 19 19 19 19 19 19 19 | |||||||

CIS STANDARDS | FOREIGN STANDARDS | ||||||||||||

Steel grade | Fraction of total mass of the elements,% | GERMANY | EUROPE | USA | BRITAIN | JAPAN | |||||||

C | Mn | Si | S | P | Cr | Ni | Cu | Grade DIN | Grade EN | Grade ASTM | Grade BS | Grade JIS | |

Ordinary QUality Cabon Steel Gost 380-94 |

|

|

|

|

| ||||||||

St 0 | 0.23 max | – | – | 0,060 | 0,070 0,040 |

| 0,30 0,30 0,30 0,30 0,30 0,30 0,30 0,30 |

| St 33 17100 St 44.2 17100 | S185 10025 |

|

|

|

Carbon Quality Structural Steel GOST 1050-88 |

|

|

|

|

| ||||||||

05kp | 0.06 max 0.05-0.12 0.07-0.14 0.12-0.19 0.17-0.24 0.22-0.30 | 0.40 max | 0.03 max | 0,040 | 0,035 | 0,10 | 0,30 | 0,30 | C 10 17200 | | SAE1005 A 572 |

|

|

GOST 4543 |

|

|

|

|

| ||||||||

15Cr | 0.12-0.18 0.17-0.23 0.24-0.32 0.36-0.44 0.15-0.21 0.09-0.16 0.09-0.16 0.17-0.24 0.16-0.22 0.17-0.23 | 0.40-0.70 | 0.17-0.37 | 0,035 | 0,035 | 0.70-1.00 | 0,30 | 0,30 | 15Cr3 17210 |

| 523 M 15 970/1 |

| |

| British Standards | |||||||||||||||||||||||

| Standard | Steel Grade | Fraction of Total mass of eleement,% | Mechanical Properties | KV,J under the t*C longitudinal/transversal | |||||||||||||||||||

| C | Mn | Si | S | P | Al | Nb | V | Ti | Nb+V +Ti 0,12 0,12 0,12 0.12 | Cr Ni Cu Mo | Gt, MPa 235 235 235 235 315 355 390 315 355 390 | Gv, MPa 400-520 400-520 400.520 400-520 440-590 490.620 510.650 440.590 490-620 510.650 | d5,% 22 22 22 22 22 21 20 22 21 20 | ||||||||||

| max or width | min | max | max | +20 27/20 | +0 27/20 31/22 34/24 41/27 | 27/20 31/22 34/24 41/27 | 27/20 31/22 34/24 41/27 | 31-22 34-24 41-27 | |||||||||||||||

| Lloyd | A B C D AH,DH,EH32, AH,DH,EH36 AH,DH,EH40 FH32 FH36 FH40 | 0,21 0,23 0.21 0.18 0.18 0.16 0.16 0,16 | 2.5C% 0.80 0,60 0,70 0.90-1.60 0.90-1.60 0.90-1.60 0.90-1.60 | 0,50 0,35 0.35 0,25 0,50 0,50 0,50 0,50 | 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 | 0,035 0,035 0,035 0,035 0,035 0,035 0,035 0,035 | 0.02- 0.05 0.02- 0.05 0.02- 0.05 0.02- 0.05 | 0.03- 0.10 0.03- 0.10 0.03- 0.10 0.03- 0.10 | 0,2 0,2 0,2 0,2 | 0,20 0,20 0,20 0,20 | 0,40 0,80 0,80 0,80 | 0,035 0,035 0,035 0,035 | 0,08 0,08 0,08 0,08 | ||||||||||

| BS4360 | 50B 50C 43A 43C | 0,20 0.20• 0.25 025 0,18 | 1.20-1.50 1,60 1,50 | 0.35- 0.50 0,50 0,50 | 0,040 0,050 0,040 | Tl+Al 0.01 | 345 – 285 285 | 490.640 – 430.580 430-580 | 18 – 20 20 | 27 | 27 | ||||||||||||

| CIS STANDARDS | FOREIGN STANDARDS | ||||||||||||

| Steel grade | Fraction of total mass of the elements,% | GERMANY | EUROPE | USA | BRITAIN | JAPAN | |||||||

| C | Mn | Si | S | P | Cr | Ni | Cu | Grade DIN | Grade EN | Grade ASTM | Grade BS | Grade JIS | |

| GOST 14959 | |||||||||||||

| 65Cr 55Si2 555I2A 605i2 60SI2V 50CrMn 50CrMnA | 0.62-0.70 0.52-0.60 0.53-0.58 0.57-0.65 0.58-0.63 0.46-0.54 0.47-0.52 | 0.90-1.20 0.60-0.90 0.60-0.90 0.60-0.90 0.60-0.90 0.90-1.00 0.80-1.00 | 0.17-0.37 1.50-2.00 1.50-2.00 1.50-2.00 1.60-2.00 0.17-0.37 0.17-0.37 | 0,035 0,035 0,025 0,035 0,025 0,035 0,025 | 0,035 0,035 0,025 0,035 0,025 0,035 0,025 | 0,30 0,30 0,30 0,30 0,30 0.90-1.20 0.90-1.20 | 0,25 0,25 0,25 0,25 0,25 0,25 0,25 | 65Mn4 55Si7 17222 65Si7 17222 55Cr3 17221 55Cr3 17221 | |||||

| GOST 1435 | |||||||||||||

| U7 U8 | 0.65-0.74 0.75-0.84 | 0.17-0.33 0.17-0.33 | 0.17-0.33 0.17-0.33 | 0,028 0,028 | 0,030 0,030 | 0,20 0,20 | 0,25 0,25 | C70W2 17350 C80W1 17350 | |||||

| GOST 19281 | |||||||||||||

| 17MnSI 17Mn1SI 14Mn2 | 0.14-0.20 0.15-0.20 0.12-0.18 | 1.0-1.4 1.15-1.6 1.2-1.6 | 0.4-0.6 0.4-0.6 0.17-0.37 | 0,04 0,04 0,04 | 0,035 0,035 0,035 | 0,03 0,03 0,03 | 0,03 0,03 0,03 | 0,03 0,03 0,03 | St 52.3 17100 17Mn4 17210 | S 355 J2G3 10025 | 50 A 572 70 A 515 70 A 516 F; G A 570 | SG365 SGV410 SGV450 SGV480 | |

| GOST 801 | |||||||||||||

| ESR-Cr15 ESR-Cr15SiMn | 0.95-1.05 0.95-1.05 | 0.17-0.37 0.40-0.65 | 0.20-0.40 0.90-1.20 | 0,020 0,020 | 0,027 0,027 | 1.30-1.65 1.30-1.65 | 0.30 min 0.30 min | 100Cr 17230 100CrMn6 17230 | 52100 A295 Gr,2 A485 | 535 A 99 970/1 535 A 99 970/1 | SUJ2 G 4805 SUJ1 G 4805 | ||

| Standard | Steel | Fraction of the total mass of the element,% | ||||

| C | Mn | SI | S | P | ||

| max or within | ||||||

| JIS G 4051 | S25C S45C | 0.22- 0.28 0.48- 0.48 | 0.30- 0.60 0.60- 0.90 | 0.15- 0.35 0.15- 0.35 | 0,035 0,035 | 0,030 0,030 |

| 1. GENERAL APPLICATION | RUSSIA | JAPAN | USA | EUROPEAN | GERMANY |

| STANDARD | GOST-16523-97 | JIS-G3132 | ASTM A635 | EN10111 | DIN1614-2 |

| STEEL GRADE | O8PS | SPHT 1 | 1008 | DD11 | SW22 |

| 2. FOR DRAWING | RUSSIA | USA | EUROPEAN | GERMANY |

| STANDARD | GOST 9045-93 | ASTM A635 | EN 10111 | DIN 1614 P 2 |

| STEEL GRADE | O8PS | 1006 DQ | DD12 | RRSTW23 |

| 3. FOR DRAWING Al KILLED | RUSSIA | USD | EUROPEAN | GERMANY |

| STANDARD | GOST 9045-93 | ASTM A635 | EN 10111 | DIN 1614 P 2 |

| STEEL GRADE | 08 YU | DQSK | DD13 | SW 24 |

| 4. STRENGTH CLASS OF 300 MPA | RUSSIA | USA | JAPAN |

| STANDARD | GOST 16523-97 | ASTM A635 | JIS G3132 |

| STEEL GRADE | 10 | 1010 | SPHT 2 |

| 5. STRENGTH CLASS OF 350 MPA | RUSSIA | USA | USA | EUROPEAN |

| STANDARD | GOST 16523-97 | ASTM A1011 | ASTM A635 | EN 10025 |

| STEEL GRADE | ST.2SP | 30,33 | 1012 | S235 JRG2, JO, JRG3 |

| 6. STRENGTH CLASS OF 400MPA | RUSSIA | USA | USA | JAPAN | JAPAN |

| STANDARD | GOST 16523-97 | ASTM A1011 | ASTM A635 | JIS G3132 | JIS 3101 |

| STEEL GRADE | 3 SP | 36 TYPE 1,2 | 1017 | SPHT3 | SS400 |

| 7. STRENGTH CLASS OF 430 MPA | RUSSIA | USA | USA | EUROPEAN |

| STANDARD | GOST 16523.97 | ASTM A1011 | ASTM A635 | EN10025 |

| STEEL GRADE | 20 | 40 | 1020 | 3275JR |

| 8. STRENGTH CLASS OF 450 MPA | RUSSIA | USA |

| STANDARD | GOST 14637-89, 380-94 | ASTM A1011, A5713 |

| STEEL GRADE | ST 3 GSP | 45 |

| 9. STRENTH CLASS OFF 500 MPA | RUSSIA | USA | JAPAN | EUROPEON |

| STANDARD | GOST 17066-94 | ASTM A1101 | JIS 3101 | EN 10025 |

| STEEL GRADE | 17 GS | 50 | SS 490 |

| HICKNESS MM | RUSSIA | JAPAN | USA | |||||||||

| GOST 21427,1 -83 | JISC-2553-86 | AISI | ASTM A-725 | ASTM A-665 | ||||||||

| GRADE | P 1.7 W/KG NOT MORE | B 100 TL, NOT LESS | GRADE | P 1.7 W/KG NOT MORE | B 5000 TL,NOT LESS | GRADE | P 1.7 W/KG NOT MORE | GRADE | P 1.7 W/KG NOT MOREf | GRADE | P 1.7 W/KG NOT MORE | |

| 0.23 | M3 M2 M1 MOH | 1.18 1.12 1.06 1.00 | ||||||||||

| 0.27 | 3405 3406 3407 3408 3409 | 1.38 1.27 1.20 1.14 1.08 | 1.61 1.62 1.68 1.71 1.72 | 27G140 27G130 27G120 27P110 27P100 | 1.40 1.30 1.20 1.10 1.00 | 1.75 1.78 1.78 1.85 1.85 | M4 M3 M1H MOH | 1.27 1.21 1.09 1.03 | 27H076 | 1.27 | 27G053 | 0.89 |

| 0.30 | 3404 3405 3406 3407 3408 3409 | 1.50 1.40 1.33 1.26 1.20 1.14 | 1.60 1.61 1.62 1.68 1.71 1.72 | 30G150 30G140 30G130 30P120 30P110 | 1.50 1.40 1.30 1.20 1.10 | 1.75 1.78 1.78 1.85 1.85 | M5 M4 M3 M2H M1H MOH | 1.39 1.32 1.23 1.17 1.11 1.05 | 30H083 | 1.39 | 30G058 | 0.97 |

| 0.35 | 3404 3405 3406 3407 3408 3409 | 1.60 1.50 1.43 1.36 1.30 1.24 | 1.60 1.61 1.62 1.68 1.71 1.72 | 35G165 35G155 3PG145 35P135 35P125 | 1.65 1.55 1.45 1.35 1.25 | 1.75 1.78 1.78 1.85 1.25 | M6 M5 M3H M2H M1H | 1.57 1.45 1.28 1.22 1.16 | 35H094 | 1.57 | 35G066 00. | 1.11 |

| ICKNESS MM | RUSSIA | JAPAN | USA | ||||||

| GOST 21427.2-83 JISC | JISC-2552-86 | AISI | ASTMA-665 | ||||||

| GRADE | P 1.5 W/KG NOT MORE | B 2500 TL,NOT LESS | GRADE | P 1.5 W/KG NOT MORE | B 5000 TL,NOT LESS | GRADE | GRADE | P 1.5 W/KG NOT MORE | |

| 0.35 | 2413 2412 2411 | 2.5 2.7 3.0 | 1.5 1.5 1.5 | 35A230 35A250 35A270 35A300 35A360 35A440 | 2.3 2.5 2.7 3.0 3.6 4.4 | 1.60 1.60 1.60 1.60 1.61 1.64 | M15 M19 M22 M27 M36 | 36F145 36F158 36F168 36F180 36F190 | 2.53 2.75 2.93 3.13 3.31 |

| 0.5 | 2414 2413 2412 2411 2312 2216 2215 2214 2213 2212 2211 2112 2111 2013 2012 2011 | 2.7 2.9 3.1 3.6 3.8 4.0 4.5 4.8 5.0 5.0 5.5 6.0 7.0 6.5 7.0 8.0 | 1.49 1.50 1.50 1.49 1.58 1.60 1.64 1.62 1.65 1.60 1.56 1.62 1.60 1.65 1.62 1.60 | 50A270 50A290 50A310 50A350 50A400 50A470 50A600 50A700 50A800 50A1000 50A1300 | 2.7 2.9 3.1 3.5 4.0 4.7 6.0 7.0 8.0 10.0 13.0 | 1.60 1.60 1.60 1.60 1.61 1.62 1.65 1.68 1.68 1.69 1.69 | M16 M19 M22 M27 M36 M43 M45 M47 | 47F168 47F174 47F185 47F190 47F205 47F230 47F305 47F40 47F475 | 2.93 3.03 3.22 3.31 3.57 4.01 5.31 6.96 8.27 |

We have our head office and a stockyard located in the UAE (Dubai). In addition to this, we have representative offices in the following countries:

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

TACO METALSASIA LIMITED © Copyright 2022. All Rights Reserved. Website Designed By: Webo.pk